Metal cutting circular saw blades

Lennartz HSS metal circular saw blades are supplied with different tooth forms and coatings - depending on the respective application - and are available in all common sizes and tooth forms.

Standard versions

Lennartz HSS - metal cutting circular saw blades are supplied in the following steel grades

HSS – S 6-5-2 – Material – No. 1.3343

HSS-E – S 6-5-2-5 – Material – No. 1.3243

Standard:

Steel grade S 6-5-2 (1.3343)

Hardness 63 - 65 HRC

Tooth forms BW, HZ

Tooth angle 18°/8°

Standard dimension

| Diameter [mm] | Cutting width [mm] | Number of teeth and tooth form for tooth pitch T [mm] | ||||||||||||

| T3 | T4 | T5 | T6 | T7 | T8 | T9 | T10 | T11 | T12 | T14 | T16 | T18 | ||

| BW | HZ | |||||||||||||

| 175 | 1.2 1.6 2.0 | 180 | 140 | 110 | 90 | 64 | ||||||||

| 200 | 1.2 1.6 1.8 2.0 | 200 | 160 | 128 | 100 | 72 | ||||||||

| 210 | 2.0 | 210 | 160 | 130 | 110 | 84 | ||||||||

| 225 | 1.2 1.6 2.0 | 220 | 180 | 150 | 120 | 90 | 80 | |||||||

| 250 | 1.6 2.0 2.5 3.0 | 240 | 200 | 160 | 128 | 110 | 100 | 80 | 64 | |||||

| 275 | 1.6 2.0 2.5 3.0 | 280 | 220 | 180 | 144 | 120 | 110 | 96 | 84 | 78 | 72 | |||

| 300 | 1.6 2.0 2.5 3.0 | 320 | 240 | 200 | 160 | 140 | 120 | 110 | 100 | 90 | 80 | |||

| 315 | 2.0 2.5 3.0 | 320 | 250 | 200 | 160 | 140 | 120 | 110 | 100 | 90 | 80 | 72 | ||

| 325 | 2.0 2.5 3.0 | 320 | 250 | 200 | 170 | 150 | 130 | 110 | 100 | 90 | ||||

| 350 | 2.0 2.5 3.0 3.5 | 350 | 280 | 220 | 180 | 160 | 140 | 120 | 110 | 90 | 80 | |||

| 370 | 2.5 3.0 3.5 | 300 | 220 | 190 | 160 | 140 | 120 | 110 | 100 | 90 | 80 | 70 | ||

| 400 | 2.5 3.0 3.5 4.0 | 320 | 250 | 200 | 180 | 160 | 140 | 128 | 100 | 90 | 80 | 70 | ||

| 425 | 3.0 3.5 4.0 | 350 | 260 | 220 | 180 | 160 | 140 | 130 | 120 | 110 | 100 | 80 | 70 | |

| 450 | 3.0 3.5 4.0 | 280 | 240 | 180 | 140 | 120 | 100 | 90 | 80 | |||||

| 500 | 3.0 3.5 4.0 5.0 | 310 | 260 | 200 | 160 | 130 | 110 | 100 | 90 | |||||

| 525 | 3.5 4.0 | 330 | 270 | 210 | 164 | 140 | 120 | 104 | 90 | |||||

| 550 | 3.0 4.0 5.0 | 340 | 280 | 220 | 170 | 140 | 120 | 110 | 100 | |||||

| 570 | 4.0 5.0 | 360 | 300 | 220 | 180 | 150 | 130 | 110 | 100 | |||||

| 600 | 4.0 5.0 | 380 | 320 | 240 | 190 | 160 | 130 | 120 | 100 | |||||

| 630 | 4.0 5.0 | 380 | 320 | 240 | 190 | 160 | 130 | 120 | 100 | |||||

| Main bore hole [mm] | Pinholes Pcs./Ø/Pitch circle Ø [mm] |

| Ø 32 | 2/8,5/45 2/11/63 2/8,5/45 2/9/50 2/12/64 2/8,5/45 4/9/50 2/12/64 |

| Ø 40 | 2/8,5/55 4/12/64 2/15/80 4/12/64 2/15/80 2/15/100 4/12/64 |

| Ø 50 | 4/15/80 4/18/100 4/15/85 |

| Ø 80 | 4/23/120 |

In addition to the standard program, special dimensions and versions are also supplied for all types of saw machines.

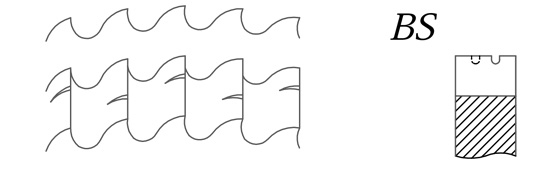

Geometries for different applications

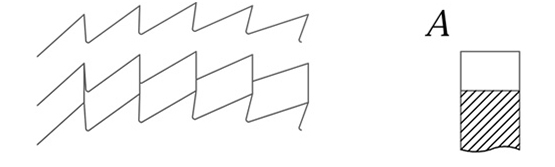

A: Standard tooth form for fine-toothed saw blades with a pitch of T = 0.8 - 3.0 mm

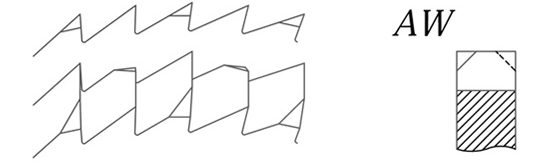

AW: Like tooth form A but with side chamfer

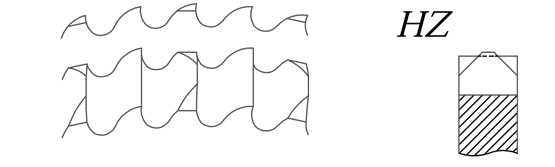

HZ (C): forward and trailing cut tooth, for the cutting of solid material, pipes and profiles with heavier wall thicknesses (>3 mm)

B: Tooth form for narrow cut saw blades with a thickness <1.3mm

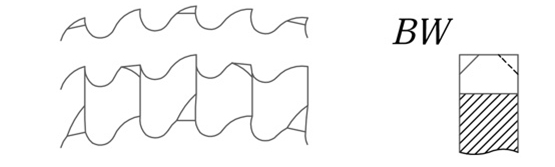

BW: Tooth form for tubes and profiles with thin wall thicknesses

BS: Standard tooth form for tubes and profiles

Cutting value recommendations

Selection of the proper cutting parameters depends on the material to be cut, the material cross section, the cooling and lubrication, the tooth geometry to be used, the condition of the sawing machine, as well as the surface treatment and coating of the saw blade. The values listed below are to be used as practical guidance aids.

Solid material

| Material | Cutting speed [m/min] | Chip thickness [mm/tooth] | Tooth pitch T with a material cross section d [mm] | ||||||

| 10-20 | 20-40 | 40-60 | 60-90 | 90-110 | 110-130 | 130-150 | |||

| up to 500 N/mm² | 30 - 50 | 0.03 - 0.06 | T5 | T8 | T10 | T12 | T14 | T16 | T18 |

| up to 800 N/mm² | 20 - 40 | 0.03 - 0.04 | T5 | T6 | T10 | T12 | T14 | T16 | T18 |

| up to 1200 N/mm² | 15 - 25 | 0.02 - 0.03 | T5 | T6 | T8 | T10 | T12 | T14 | T14 |

| Stainless steel | 10 - 30 | 0.01 - 0.03 | T5 | T6 | T8 | T10 | T12 | T14 | T14 |

| Cast iron | 15 - 40 | 0.04 - 0.05 | T5 | T6 | T8 | T11 | T14 | T16 | T16 |

| Aluminium | 80 - 1500 | 0.04 - 0.09 | T6 | T8 | T12 | T16 | T18 | T20 | T20 |

| Copper | 200 - 300 | 0.04 - 0.06 | T6 | T8 | T10 | T13 | T15 | T17 | T19 |

| Bronze | 90 - 300 | 0.04 - 0.06 | T6 | T8 | T10 | T13 | T15 | T17 | T19 |

| Brass | 350 - 600 | 0.04 - 0.08 | T6 | T10 | T12 | T14 | T17 | T19 | T20 |

Tubes and profiles

| Material | Cutting speed [m/min] | Chip thickness [mm/tooth] | Tooth pitch T with a material cross section d [mm] | |||||||

| <1.0 | 1.0 - 1.5 | 1.5 - 2.0 | 2.0 - 3.0 | 3.0 - 4.0 | 4.0 - 5.0 | 5.0 - 6.0 | 6.0 - 8.0 | |||

| up to 500 N/mm² | 40 - 80 | 0.03 - 0.06 | T3 | T4 | T5 | T5 | T6 | T8 | T9 | T10 |

| up to 800 N/mm² | 30 - 60 | 0.03 - 0.04 | T3 | T4 | T4 | T5 | T6 | T8 | T9 | T10 |

| up to 1200 N/mm² | 20 - 40 | 0.02 - 0.03 | T3 | T3 | T4 | T5 | T5 | T7 | T8 | T9 |

| Stainless steel | 5 - 40 | 0.01 - 0.03 | T3 | T3 | T4 | T5 | T6 | T8 | T9 | T10 |

| Aluminium | 80 - 1500 | 0.04 - 0.09 | T4 | T5 | T6 | T7 | T8 | T10 | T12 | T12 |

| Copper | 200 - 500 | 0.04 - 0.05 | T4 | T5 | T6 | T7 | T8 | T10 | T12 | T12 |

| Bronze | 90 - 350 | 0.04 - 0.06 | T4 | T5 | T6 | T7 | T8 | T10 | T12 | T12 |

| Brass | 350 - 900 | 0.04 - 0.08 | T4 | T5 | T6 | T7 | T8 | T10 | T12 | T12 |

Surface treatment

The following versions can be supplied:

- blank

- steam treated

- coated

TiN, TiAlN, TiCN

Further versions upon request.