Ecomax

ECOmax saw blades are special thin circular saw blades for the high-performance cutting of steel and non-ferrous metals. They are available in different versions, cutting materials and coatings. Through this, ECOmax saw blades are always individually tailored to the respective application. They are suitable for stationary mass cutting saws as well as for trailing or so-called flying saws.

High performance circular saw blades for all common stationary mass cutting circular saw machines

ECOmax - Alpha

- Cermet tipped

- For the cutting of solid materials from low to high-alloy steels

- Smooth cutting surfaces

ECOmax - Beta

- Cermet tipped

- For the cutting of solid materials from low to high-alloy Steels

- High contact surface

- optimized cutting edge geometry

ECOmax – Plus

- Cermet tipped

- For the cutting of solid materials from low to high-alloy steels

- Increase of the cutting performance, thanks to increased cutting parameters, as well as through an individual coating

Tooth number recommendation ECOmax-Alpha / EComax-Beta / ECOmax Plus

Sawing of solid materials

ECOmax – Sigma

- Carbide-tipped

- For the separation of solid material with smaller and larger diameters and a high strength = >1100N/mm2

- Increase of the cutting performance, thanks to increased cutting parameters, as well as through an individual coating

Application examples ECOmax Sigma

| Material dimensions | Material data | Saw blade data | Machine | Performance | ||||

| Quality | Tensile strength [N/mm²] | Diameter | Number of teeth [N/mm²] | Number of cuts | Attained m² | |||

| 60 | 16MnCr5 | 610 | 360 | 80 | Ficep | 14154 | 40 | |

| 95 | 38MnSiV5 | 1000 | 350 | 80 | Rattunde | 3656 | 33 | |

ECOmax – X

- Carbide-tipped

- For the cutting of high-alloy and stainless steels, as well as titanium and nickel-based alloys

- Minimal waste

- Individually adapted coatings

- Economic separation through high contact surfaces

Application examples ECOmax X

| Material dimensions | Material data | Saw blade data | Machine | Performance | ||||

| Quality | Tensile strength [N/mm²] | Diameter | Number of teeth [N/mm²] | Number of cuts | Attained m² | |||

| 90 | TiAl6V4 | 900 | 425 | 80 | MFL | 1886 | 12 | |

| 121 | X2CrNiMo18-14-3 | 730 | 420 | 60 | Behringer | 466 | 6.98 | |

| 55 | X6CrNiMoTi17-12-2 | 530 | 460 | 80 | Ficep | 2100 | 5 | |

ECOmax – NF

- Carbide-tipped

- For the cutting of non-ferrous metals and alloys, such as aluminium, copper, brass and bronze

- Minimal waste

- High contact surface and smooth cutting surface

High performance circular saw blades for all rotating and stationary pipe and profile saws

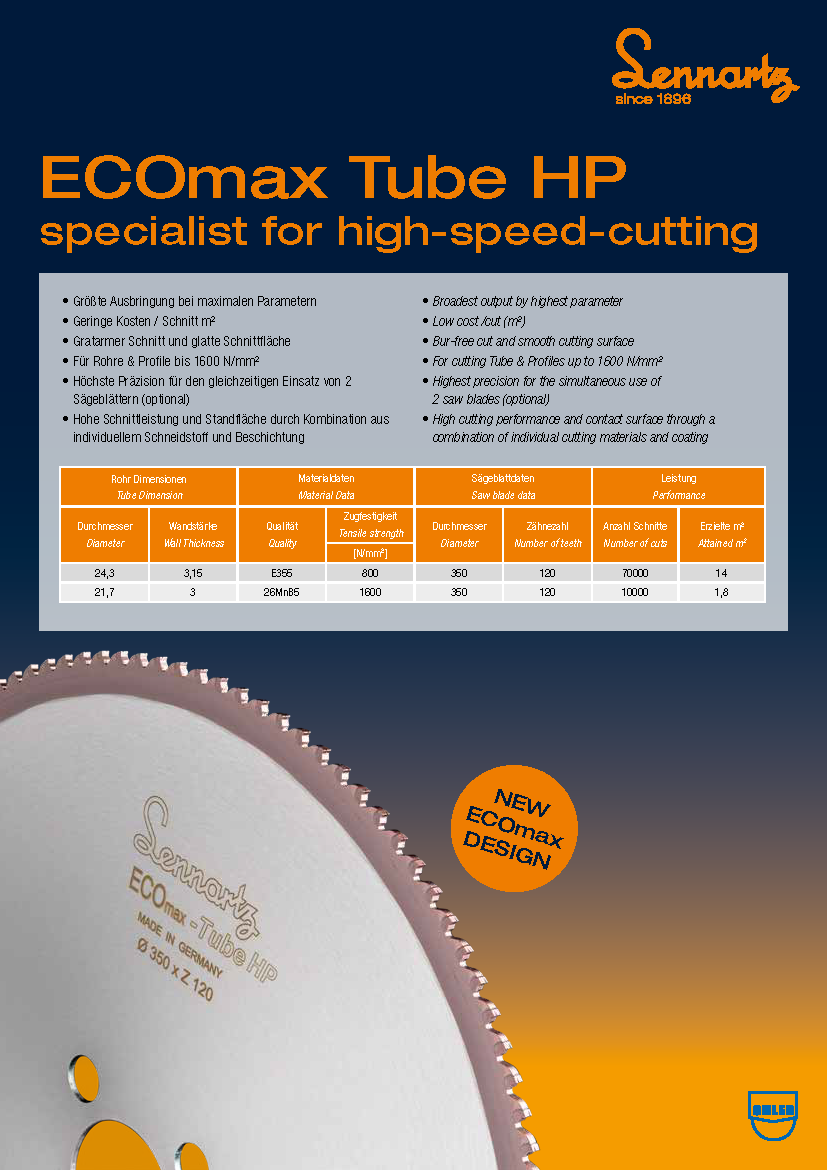

ECOmax – Tube

- Highest precision for the simultaneous use of 2 saw blades (optional)

- High cutting performance and contact surface through a combination of individual cutting materials and coatings

- Burr-free cut and smooth cutting surface

- Salable surface quality

Application examples ECOmax Tube

| Pipe dimensions | Material data | Saw blade data | Machine | Performance | ||||

| Diameter | Wall thickness | Quality | Tensile strength [N/mm²] | Diameter | Number of teeth | Number of cuts | Attained m² | |

| 76.2 | 4.2 | SAE 1010 | 575 | 550 | 150 | Oto Mills | 4100 | 3.9 |

| 24.3 | 3.15 | E355 | 800 | 350 | 120 | Rattunde | 70000 | 14 |

| 21.7 | 3 | 26MnB5 | 1600 | 350 | 120 | Rattunde | 10000 | 1.8 |

| 42.1 | 3.4 | S355 | 460 | 500 | 140 | Oto Mills | 14000 | 6.3 |

ECOmax – Tube

ECOmax – Scarf

- Highest precision for the simultaneous use of 2 saw blades (optional)

- Developed and suitable for the cutting of tubes and profiles with a rough internal welding seam

- High contact surface through a special tooth form and geometry in combination with a coating

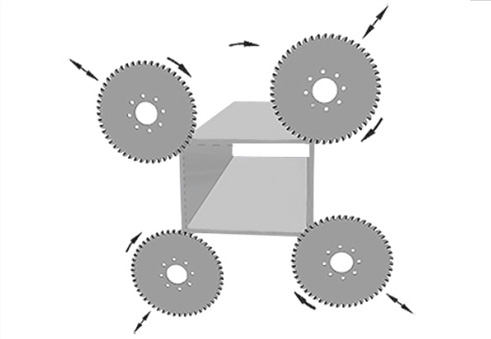

ECOmax – Multi

- The highest precision for the simultaneous use of 4 saw blades (optional) in a rotational sawing process for seamless and welded tubes and sections

- High cutting performance and contact surface through a combination of individual cutting materials and coatings

- Burr-free cut and smooth cutting surface

Application examples ECOmax Multi

| Pipe dimensions | Material data | Saw blade data | Machine | Performance | ||||

| Diameter | Wall thickness | Quality | Tensile strength [N/mm²] | Diameter | Number of teeth | Number of cuts | Attained m²/blade | |

| ø 114 | 8.2 | J55 | 551 | 380 | 66 | Oto Mills | 3500 | 4.2 |

| 160x160 | 7 | ST52 | 550 | 380 | 70 | SMS | 1800 | 4.7 |

| 120x120 | 8 | ST52 | 550 | 380 | 70 | SMS | 2480 | 4.6 |

Werkstoff- und Einsatzempfehlungen

| Werkstoffgruppe | DIN | Beste Wahl | Geeignet | Bedingt geeignet |

|---|---|---|---|---|

| Baustähle | St 44 | ECOmax ECOmax PLUS ECOmax TUBE ECOmax SCARF ECOmax MULTI | ECOmax SIGMA | ECOmax X |

| Baustähle | ST 52 | ECOmax ECOmax PLUS ECOmax TUBE ECOmax SCARF ECOmax MULTI | ECOmax SIGMA | ECOmax X |

| Baustähle | ST 37 | ECOmax ECOmax PLUS ECOmax TUBE ECOmax SCARF ECOmax MULTI | ECOmax SIGMA | ECOmax X |

| Vergütungs- und Nitrierstähle | C 15 | ECOmax ECOmax PLUS | ECOmax SIGMA | ECOmax X ECOmax TUBE |

| Vergütungs- und Nitrierstähle | C 45 | ECOmax ECOmax PLUS | ECOmax SIGMA | ECOmax X ECOmax TUBE |

| Vergütungs- und Nitrierstähle | C 60 | ECOmax ECOmax PLUS | ECOmax SIGMA | ECOmax X ECOmax TUBE |

| Vergütungs- und Nitrierstähle | 42 CrMo 4 | ECOmax ECOmax PLUS | ECOmax SIGMA | ECOmax X ECOmax TUBE |

| Vergütungs- und Nitrierstähle | 34 CrNiMo 6 | ECOmax ECOmax PLUS | ECOmax SIGMA | ECOmax X ECOmax TUBE |

| Vergütungs- und Nitrierstähle | 34 CrAINi 7 | ECOmax ECOmax PLUS | ECOmax SIGMA | ECOmax X ECOmax TUBE |

| Feder- und Wälzlagerstähle | 50 CrV 4 | ECOmax PLUS ECOmax SIGMA ECOmax X | ECOmax | ECOmax TUBE |

| Feder- und Wälzlagerstähle | 100 Cr 6 | ECOmax PLUS ECOmax SIGMA ECOmax X | ECOmax | ECOmax TUBE |

| Nichtrostende Stähle | X 40 CrMoV 51 | ECOmax X | ECOmax SIGMA | ECOmax ECOmax PLUS |

| Nichtrostende Stähle | X 5 CrNiMo 17 12 2 | ECOmax X | ECOmax SIGMA | ECOmax ECOmax PLUS |

| Nichtrostende Stähle | X 20 Cr 13 | ECOmax X | ECOmax SIGMA | ECOmax ECOmax PLUS |

| Nichtrostende Stähle | X 2 CrNIMo 18 14 3 | ECOmax X | ECOmax SIGMA | ECOmax ECOmax PLUS |

| Vergütete Stähle | 1000 - 1600 N/mm² | ECOmax SIGMA | ECOmax X | ECOmax ECOmax PLUS ECOmax TUBE |

| Grauguss | EN-GJL-200-300 | ECOmax X | ECOmax PLUS ECOmax SIGMA | ECOmax TUBE |

| Grauguss | EN-GJS-400-15 | ECOmax X | ECOmax PLUS ECOmax SIGMA | ECOmax TUBE |

| Nahtlos- und Schweissrohre | S355 | ECOmax SIGMA ECOmax TUBE ECOmax MULTI | ECOmax SCARF | |

| Nahtlos- und Schweissrohre | FE510 | ECOmax SIGMA ECOmax TUBE ECOmax MULTI | ECOmax SCARF | |

| Nahtlos- und Schweissrohre | 34MnB5 ≤ 1600 N/mm2 | ECOmax SIGMA ECOmax TUBE ECOmax MULTI | ECOmax SCARF | |

| Nahtlos- und Schweissrohre | API | ECOmax SIGMA ECOmax TUBE ECOmax MULTI | ECOmax SCARF | |

| Rohre u. Profile mit innenlieg., geschabter Schweißnaht | S355 | ECOmax ECOmax SCARF | ECOmax TUBE ECOmax MULTI | |

| Rohre u. Profile mit innenlieg., geschabter Schweißnaht | FE510 | ECOmax ECOmax SCARF | ECOmax TUBE ECOmax MULTI | |

| Rohre u. Profile mit innenlieg., geschabter Schweißnaht | 34MnB5 ≤ 1600 N/mm2 | ECOmax ECOmax SCARF | ECOmax TUBE ECOmax MULTI | |

| Rohre u. Profile mit innenlieg., geschabter Schweißnaht | API | ECOmax ECOmax SCARF | ECOmax TUBE ECOmax MULTI | |

| Aluminium Guss und Knetlegierungen | ≤ 500 N/mm2 | ECOmax NF | ECOmax PLUS ECOmax SIGMA | |

| Kupfer, Kupferlegierungen | ≤ 400 N/mm2 | ECOmax NF | ECOmax PLUS ECOmax SIGMA | |

| Messing, kurz- und langspanend | ≤ 600 N/mm2 | ECOmax NF | ECOmax PLUS ECOmax SIGMA | |

| Bronze | ≤ 850 N/mm2 | ECOmax NF | ECOmax PLUS ECOmax SIGMA |

A selection of suitable sawing machines for the ECOmax saw blades

| Manufacturer | Type | Diameter | Borehole | Connection dimensions | Blade thickness | Cutting width |

|---|---|---|---|---|---|---|

| Amada | CM - 65 AN | 280 | 40 | 2/11/80 | 1.75 | 2.0 |

| Amada | CM - 75 CNC | 285 | 40 | 2/11/80 | 1.75 | 2.0 |

| Amada | CM - 100 AN | 360 | 40 | 4/11/90 | 2.25 | 2,6/2,7 |

| Amada | CM - 100 CNC | 360 | 40 | 4/11/90 | 2.25 | 2,6/2,7 |

| Amada | CM - 150 AN | 460 | 50 | 4/11/90 | 2.25 | 2,6/2,7 |

| Behringer/Eisele | HCS 70 | 250/285 | 40 | 2/12/65+2/15/80 | 1.75 | 2.0 |

| Behringer/Eisele | HCS 90 | 285 | 40 | 2/12/65+2/15/80 | 1.75 | 2.0 |

| Behringer/Eisele | HCS 90 | 315 | 40 | 2/12/65+2/15/80 | 1.9 | 2.2 |

| Behringer/Eisele | HCS 90 | 360 | 40 | 2/12/65+2/15/80 | 2.25 | 2,6/2,7 |

| Behringer/Eisele | HCS 130 | 360/420 | 40 | 2/12/65+2/15/80 | 2.25 | 2,6/2,7 |

| Behringer/Eisele | HCS 150 | 360/420/460 | 40 | 2/12/65+2/15/80 | 2.25 | 2,6/2,7 |

| Bewo | ECH-108-M | 250 | 40 | 4/12/64 | 1.75 | 2.0 |

| Everising | P - 65 A | 280 | 32 | 2/10,5/63 | 1.75 | 2.0 |

| Everising | P - 100 A | 360 | 40 | 4/10,5/90 | 2.25 | 2,6/2,7 |

| Everising | P - 150 A | 460 | 50 | 4/14/90 | 2.25 | 2,6/2,7 |

| Exactcut | MAC60 | 250 | 32 | 4/9/50 | 1.75 | 2.0 |

| Exactcut | WSM-60-HM | 275 | 32 | 4/9/50 | 1.75 | 2.0 |

| Exactcut | MAC60 | 285 | 32 | 4/9/50 | 1.75 | 2.0 |

| Ficep | S 35 | 360 | 50 | 4/16/80 | 2.25 | 2,6/2,7 |

| Ficep | S 50 | 460 | 50 | 4/16/80 | 2.25 | 2,6/2,7 |

| Itec Dualcut | DC - 65 | 285 | 32 | 4/11/63 | 1.75 | 2.0 |

| Itec Dualcut | DC - 85 | 360 | 40 | 4/11/63 | 2.25 | 2,6/2,7 |

| Kaltenbach | KMR 100AP | 370 | 50 | 4/15/80 | 2.25 | 2,6/2,7 |

| Kaltenbach | MSK 471 | 460 | 50 | 4/15/80 | 2.25 | 2,6/2,7 |

| Kasto | Speed C7/ WAC70 | 250/285 | 32 | 4/9/50 | 1.75 | 2.0 |

| Kasto | Speed C9 | 250/285 | 32 | 4/9/50 | 1.75 | 2.0 |

| Kasto | Speed C9 | 315 | 32 | 4/9/50 | 1.9 | 2.2 |

| Kasto | Speed C14 | 360/425 | 50 | 4/15/80 | 2.25 | 2,6/2,7 |

| Kentai | KTC-65 | 250/285 | 32 | 4/9/50+4/11/63 | 1.75 | 2.0 |

| Kentai | KTC-85 | 315 | 32 | 4/9/50+4/11/63 | 1.9 | 2.2 |

| MEGA | CS-65 | 285 | 32 | 2/10,5/45 | 1.75 | 2.0 |

| Missler | CS 100 | 360 | 40 | 4/10/90 | 2.25 | 2,6/2,7 |

| Nishijima | NHC-050NA | 250 | 32 | 4/11/63 | 1.75 | 2.0 |

| Nishijima | NHC-070NA | 285 | 32 | 4/11/63 | 1.75 | 2.0 |

| Nishijima | NHC-100NA | 360 | 50 | 4/16/80 | 2.25 | 2,6/2,7 |

| Nishijima | NHC-150NA | 460 | 50 | 4/21/90 | 2.25 | 2,6/2,7 |

| Noritake | NCS-2/65 | 280 | 40 | 2/11/80 | 1.75 | 2.0 |

| Noritake | NSC-2/100 | 360 | 40 | 4/11/90 | 2.25 | 2,6/2,7 |

| Noritake | NSC-2/150 | 460 | 50 | 4/11/90 | 2.25 | 2,6/2,7 |

| Rattunde | ACS | 350/360 | 50 | 4/16/80 | 2.5 | 2.8 |

| RSA Rasacut | SC/MC/SK/OC/TC | 250/315 | 40 | 4/10/63 | 1,75/1,9 | 2,0/2,2 |

| RSA Rasacut | CC90/SH90 | 250/315 | 40 | 4/10/63 | 1,75/1,9 | 2,0/2,2 |

| RSA Rasacut | XXL/CC150/SH150 | 350/460 | 50 | 4/12/80 | 2,25/2,5 | 2.7 |

| Simec | SIMAX 100 | 360 | 50 | 4/16/80 | 2.25 | 2,6/2,7 |

| Simec | SIMAX 150 | 460 | 50 | 4/21/90 | 2.25 | 2,6/2,7 |

| Sinico | TOP 2000 | 360 | 50 | 4/16/80 | 2.25 | 2.6 |

| SOCO | SA - 60 - CNC | 250 / 280 | 32 | 2/11/63 | 1.75 | 2.0 |

| Tsune | TK 5C-50 GL | 250/285 | 32 | 4/11/63 | 1.75 | 2.0 |

| Tsune | TK 5C-102 GL | 360/420 | 50 | 4/15/80 | 2.25 | 2,6/2,7 |