Accessories sawing technology

Lennartz will provide you with all the key components which influence the proper and economical saw cut. In addition to the actual saw blade these are products for the blade cooling, measuring equipment and other sawing technology accessories. Contact us - we will gladly consult you!

Air-cooler, coolant and lubricants

The Lennartz Aircooler transforms normal compressed air into ultra cold air down to -30°C according to the Joule Thomson effect. The temperature depends on the generated air flow l/min and the level of pressure. Through a dry cooling of the main blade, the correct straightening and tension condition of the saw blade is ensured even under the toughest conditions without leaving any residue.

Coolant and lubricants positively influence the sawing process. We will support you during the selection of the appropriate minimum lubricant quantity or the proper cooling lubricant for your applications. The cooling lubricant is supplied worldwide in containers of 5 L, 20 L, 60 L and 200 L.

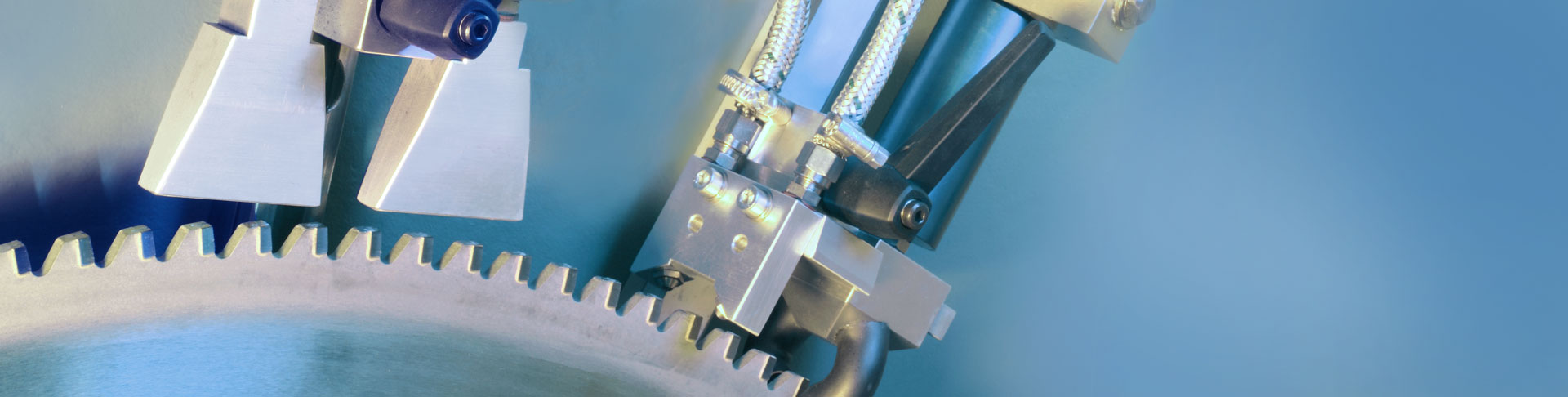

Lennartz micro dosing systems

Dosing systems with minimal lubrication to improve the cutting process, which were developed specially for the circular sawing. The modular designed systems consist of the enclosure in which the pump blocks, the impulse drivers for the pump stroke and the solenoid valves are housed. Additional units form the reservoir for the lubricant and the emulsion. The nozzles are either designed as flexo-pipe, U-nozzle or jacketed-jet nozzles.

Sawtooth overhang gauge

- Double-sided readable.

- Measuring range 2 mm

- Display range 1 mm

- readable through index lines for every 0.05 mm

- Display blade can be set to 0 point

- With an additional, adjustable ring as a set-point controller

- Length 93 mm, height 54 mm, thickness 23 mm

- Weight 120 g

Angle measuring devices

Optical/mechanical device for the measurement of tooth angles (hook and clearance angle) and the tooth height difference.

Concentricity and axial run-out and tension testing machine from the company MUMTEC

Hard facts for the optimal concentricity, axial run-out and perfect tension are among the quality-decisive factors of the Vmax. After each new set up, these characteristics should be measured economically on P-series machines. The individual measured values provide each user with the necessary transparency to continuously manage the concentricity, axial run-out and tension characteristics of the Vmax, thus ensuring the greatest possible smooth running as well as the maximum service life.

The P-series. Perfect control of the concentricity, axial run-out and tension

| Technical data | P-1200 | P-1600 | P-2000 | P-3500 |

|---|---|---|---|---|

| Saw blade diameter | 250 - 1200 mm | 250 - 1600 mm | 250 - 2000 mm | 250 - 3500 mm |

| Bore diameter | ≥ 20 mm | ≥ 20 mm | ≥ 20 mm | ≥ 50 mm |

| Dimensions | 1500 x 1000 x 1000 mm | 1500 x 1200 x 1000 mm | 1500 x 1400 x 1000 mm | 3000 x 2000 x 1500 mm |

| Weight approx. | 300 kg | 350 kg | 500 kg | 3000 kg |

| Pneumatic connection | 6 bar | 6 bar | 6 bar | 6 bar |

| Electrical conn. | 230 V 50 Hz / 400 V 3 ~ 50 Hz | 230 V 50 Hz / 400 V 3 ~ 50 Hz | 230 V 50 Hz / 400 V 3 ~ 50 Hz | 230 V 50 Hz / 400 V 3 ~ 50 Hz |