Band saw blades

The base material for the bi-metal band saw blades consists of a tempered alloy steel, which is inextricably bonded to the HSS in M42 or M51 using a laser beam welding process. The uniformity and reliable high quality of our bi-metal band saw blades is guaranteed through a mechanical and thermal processing in modern production facilities.

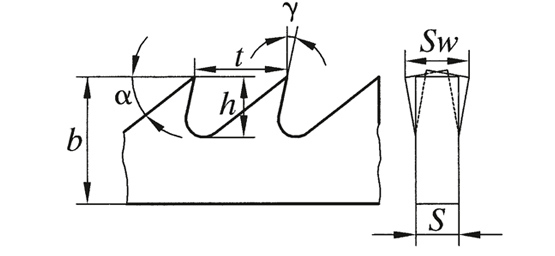

Band sawing blade geometry

t = tooth pitch

γ = rake angle

α = clearance angle

Sw = arrangement width

b = band width

S = band thickness

h = depth of the tooth

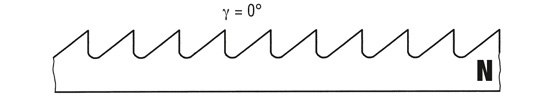

Tooth forms

Standard tooth form N

with a rake angle of 0° ~ + 4°

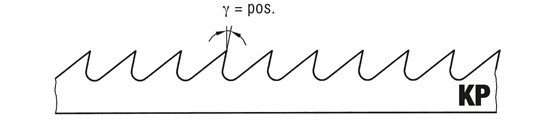

Claw (hook) tooth form KP

with a positive rake angle

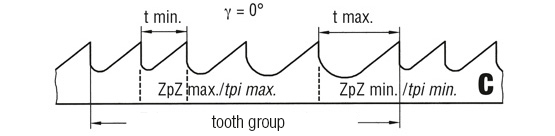

Combo-tooth form C

with a variable tooth pitch in a tooth group with a rake angle of 0°~+4°

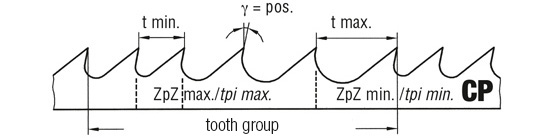

Combo-tooth form CP

with a variable tooth pitch in a tooth group with a positive rake angle

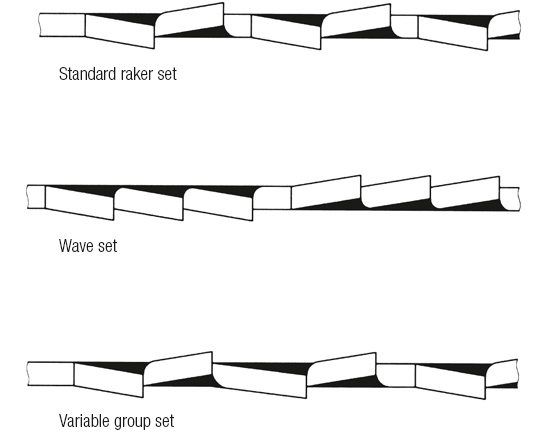

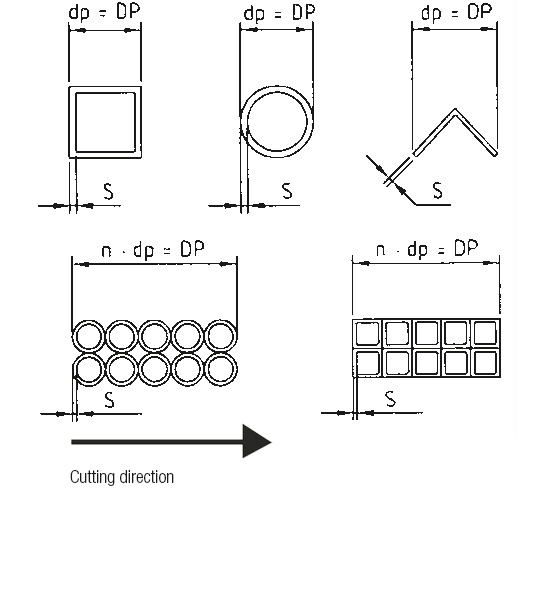

Types of tooth setting

The fundamental prerequisite for the trouble free utilization of the band saw blades is the application specific arrangement width (Sw), commonly known as the "set". Thereby, a cutting joint is created during the sawing process, which is wider than the width of the band (S) and thus prevents a jamming.

The versions Profiler and Alu-Master are manufactured with a larger set width to suit the specific application requirements.

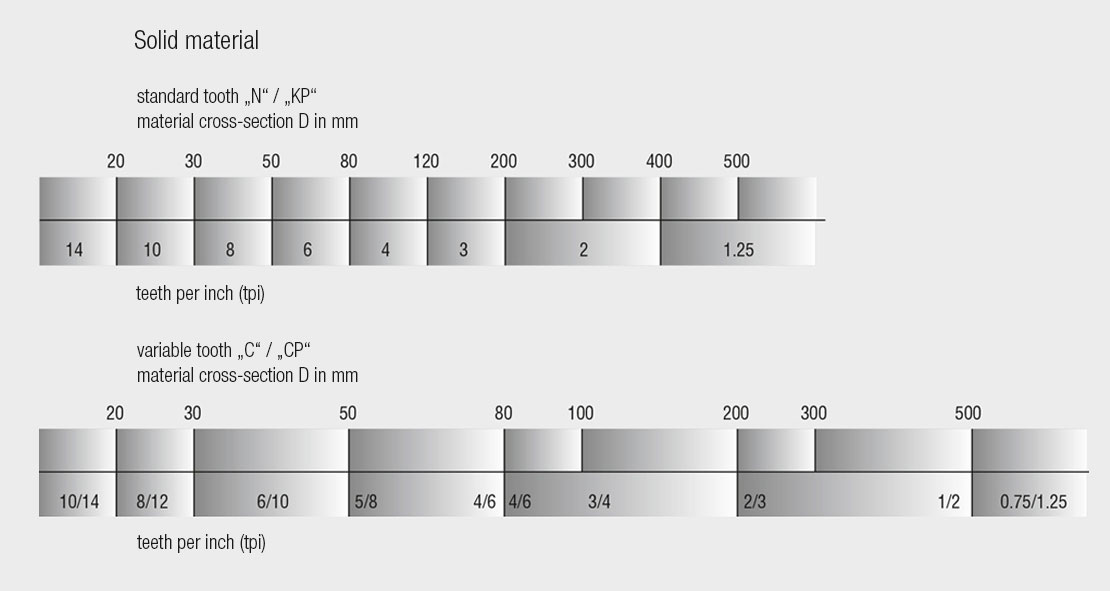

Technical guide values for M42 bi-metal band saw blades

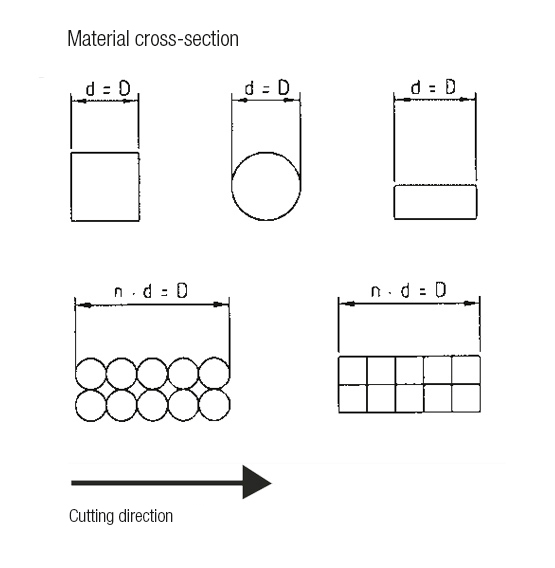

When using bi-metal band saw blades, the tooth form selection (TPI) should primarily be based on the cross-section of the material to be cut, and secondarily on the actual material. For the low-vibration cutting of problematic or varying cutting material cross-sections it is advisable to use the combination tooth “C” or “CP” with a variable tooth pitch.

| Ø/mm | 14/18 | 10/14 | 8/12 | 6/10 | 5/8 | 4/6 | 3/4 | 2/3 | 1,4/2 | 1,1/1,4 | 0,75/1,25 | 0,5/0,9 | ZPZ |

| 20 | • | • | • | 14 | |||||||||

| 30 | • | • | • | 10 | |||||||||

| 40 | • | • | • | 8 | |||||||||

| 50 | • | • | • | • | 6 | ||||||||

| 60 | • | • | • | 6 | |||||||||

| 70 | • | • | • | • | 6 | ||||||||

| 80 | • | • | • | 4 | |||||||||

| 90 | • | • | 4 | ||||||||||

| 100 | • | • | • | 4 | |||||||||

| 150 | • | • | 3 | ||||||||||

| 200 | • | • | 2 | ||||||||||

| 250 | • | • | 2 | ||||||||||

| 300 | • | • | 2 | ||||||||||

| 350 | • | 2 | |||||||||||

| 400 | • | 1,25 | |||||||||||

| 450 | • | • | 1,25 | ||||||||||

| 500 | • | • | 1,25 | ||||||||||

| 510 | • | • | 1,25 | ||||||||||

| 520 | • | • | • | 1,25 | |||||||||

| 530 | • | • | 1,25 | ||||||||||

| 540 | • | • | 1,25 | ||||||||||

| 550 | • | • | • | 1,25 | |||||||||

| 600 | • | • | • | 1,25 | |||||||||

| 700 | • | • | • | 1,25 | |||||||||

| 1000 | • | • | 1,25 |

Tooth pitch to be selected

| Ø/mm | 2 | 4 | 6 | 8 | 10 | 15 | 25 | 35 | 50 | 65 | 75 | 100 | 130 | 150 | 200 |

| 20 | 22 | 10/14 | 10/14 | ||||||||||||

| 40 | 22 | 10/14 | 8/12 | 6/10 | 5/8 | ||||||||||

| 60 | 18 | 10/14 | 8/12 | 6/10 | 5/8 | 5/8 | 4/6pos | ||||||||

| 80 | 18 | 10/14 | 8/12 | 6/10 | 5/8 | 4/6pos | 4/6pos | 3/4pos | |||||||

| 90 | 14 | 8/12 | 6/10 | 5/8 | 4/6pos | 4/6pos | 4/6pos | 3/4pos | |||||||

| 100 | 14 | 8/12 | 6/10 | 5/8 | 4/6pos | 4/6pos | 4/6pos | 3/4pos | |||||||

| 110 | 14 | 8/12 | 6/10 | 5/8 | 4/6pos | 4/6pos | 4/6pos | 3/4pos | |||||||

| 120 | 14 | 8/12 | 6/10 | 5/8 | 4/6pos | 4/6pos | 3/4pos | 3/4pos | 3/4pos | ||||||

| 130 | 10/14 | 6/10 | 5/8 | 5/8 | 4/6pos | 4/6pos | 3/4pos | 3/4pos | 2/3pos | ||||||

| 140 | 10/14 | 6/10 | 5/8 | 5/8 | 4/6pos | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | |||||

| 150 | 10/14 | 6/10 | 5/8 | 5/8 | 4/6pos | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | |||||

| 160 | 10/14 | 6/10 | 5/8 | 4/6 | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 2/3pos | ||||

| 170 | 10/14 | 6/10 | 5/8 | 4/6 | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 2/3pos | ||||

| 180 | 10/14 | 6/10 | 5/8 | 4/6 | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 2/3pos | ||||

| 190 | 10/14 | 6/10 | 5/8 | 4/6 | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 2/3pos | ||||

| 200 | 10/14 | 6/10 | 5/8 | 4/6 | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 1,4/2pos | 2/3pos | ||||

| 220 | 10/14 | 6/10 | 5/8 | 4/6 | 4/6pos | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 1,4/2pos | 2/3pos | ||||

| 250 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | |||

| 300 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | ||

| 350 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | |

| 400 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | 1,4/2pos | |

| 500 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 |

| 600 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 |

| 700 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 |

| 800 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 |

| 1000 | 8/12 | 5/8 | 4/6 | 4/6 | 3/4pos | 3/4pos | 2/3pos | 2/3pos | 2/3pos | 1,4/2pos | 1,4/2pos | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 | 0,75/1,25 |

Variable-Cutter / Variable-Cutter Plus M42 bi-metal band saw blades

The Variable-Cutter with a “C” combo-tooth form, and Variable-Cutter Plus with a combo-tooth form and positive rake angle "CP” enable a particularly low-vibration operation when cutting solid materials and sections.

Application:

- Solid material, profiles, single and bundle cuts

- Iron materials up to approx. 1400 N/mm² tensile strength

- Non-ferrous metals

| Band width b x band thickness S | TPI | ||||||||||

| mm | Inch | 0,75/1,25 | 1,1/1,4 | 1,4/2 | 2/3 | 3/4 | 4/6 | 5/8 | 6/10 | 8/12 | 10/14 |

| 6 x 0.90 | 1/4 x 0,035 | C | |||||||||

| 10 x 0.90 | 3/8 x 0.035 | ||||||||||

| 13 x 0.65 | 1/2 x 0.025 | C | C | C | |||||||

| 13 x 0.90 | 1/2 x 0.035 | C | C | C | |||||||

| 20 x 0.90 | 3/4 x 0.035 | C/CP | C/CP | C | C | C | |||||

| 27 x 0.90 | 1 1/16 x 0.035 | CP | C/CP | C/CP | C/CP | C | C | C | |||

| 34 x 1.10 | 1 3/8 x 0.042 | CP | C/CP | C/CP | C/CP | C | C | ||||

| 41 x 1.30 | 1 5/8 x 0.050 | CP | CP | C/CP | C/CP | C/CP | |||||

| 54 x 1.30 | 2 1/8 x 0,50 | CP | CP | CP | CP | ||||||

| 54 x 1.60 | 2 1/8 x 0,063 | CP | CP | CP | CP | CP | CP | ||||

| 67 x 1.60 | 2 5/8 x 0,063 | CP | CP | CP | CP | CP | CP | ||||

| 80 x 1.60 | 3 1/8 x 0.63 | CP | CP | CP | CP | CP | |||||

Constant-Cutter / Constant-Cutter Plus M42 bi-metal band saw blades

Constant-Cutter with standard tooth form "N" and Constant-Cutter Plus with a claw-type tooth form "KP" are ideally suited to meet standard requirements when cutting solid material.

Application:

- Solid material, profiles, single and bundle cuts

- Iron materials up to approx. 1400 N/mm² tensile strength

- Non-ferrous metals

M42 bi-metal band saw blades

Constant-Cutter/ Constant Cutter Plus

| Band width b x band thickness S | TPI | |||||||||

| mm | Inch | 1.25 | 2 | 3 | 4 | 6 | 8 | 10 | 14 | 18 |

| 6 x 0.90 | 1/4 x 0,035 | KP | N | N | ||||||

| 10 x 0.90 | 3/8 x 0.035 | KP | N | N | ||||||

| 13 x 0.65 | 1/2 x 0.025 | KP | KP | N | N | |||||

| 13 x 0.90 | 1/2 x 0.035 | KP | KP | KP | N | N | ||||

| 20 x 0.90 | 3/4 x 0.035 | KP | KP | N | N | N | N | |||

| 27 x 0.90 | 1 1/16 x 0.035 | KP | N/KP | N/KP | N | N | N | |||

| 34 x 1.10 | 1 3/8 x 0.042 | KP | KP | KP | N | |||||

| 41 x 1.30 | 1 5/8 x 0.050 | KP | KP | |||||||

| 54 x 1.30 | 2 1/8 x 0,50 | KP | ||||||||

| 54 x 1.60 | 2 1/8 x 0,063 | KP | ||||||||

| 67 x 1.60 | 2 5/8 x 0,063 | KP | ||||||||

Variable-Cutter / Variable-Cutter Plus / Variable Cutter Plus B

Anwendung:

• Vollmaterial, Profile, Einzel- und Bündelschnitte

• Eisenwerkstoffe bis ca. 1400 N / mm2 Zugfestigkeit

• NE-Metalle

| Bandbreite b x Bandstärke S | 0,75/1,25 | ||||||||||

| blade width b x blade thickness S | Zoll /Inch | 1,1/1,4 | 1,4/2 | 2/3 | 3/4 | 4/6 | 5/8 | 6/10 | 8/12 | 10/14 | 14/18 |

| 6 x 0,90 mm | 1/4 x 0,035 | C 1 | |||||||||

| 10 x 0,90 mm | 3/8 x 0,035 | C 1 | |||||||||

| 13 x 0,65 mm | 1/2 x 0,025 | C | C | C | |||||||

| 13 x 0,90 mm | 1/2 x 0,035 | C | C | C | |||||||

| 20 x 0,90 mm | 3/4 x 0,035 | C/CP | C | C | C | C | C | ||||

| 27 x 0,90 mm | 1 1/16 x 0,035 | CP | C/CP* | C/CP* | C* | C | C | C | C | ||

| 34 x 1,10 mm | 1 3/8 x 0,035 | CP | C/CP* | C/CP* | C* | C | C | ||||

| 41 x 1,30 mm | 1 5/8 x 0,050 | C | CP | C/CP* | C/CP* | C/CP* | |||||

| 54 x 1,30 mm | 2 1/8 x 0,050 | CP | CP | C/CP | CP | ||||||

| 54 x 1,60 mm | 2 1/8 x 0,063 | CP | CP | CP | C/CP | C/CP | |||||

| 67 x 1,60 mm | 2 5/8 x 0,063 | CP | CP | CP | CP | CP 1 |

Profiler M42 bi-metal band saw blades

Profiler with combo-tooth form "C" and larger arrangement width "Sw" are particularly suitable for the cutting of large steel beams and profiles with large cross-sections.

Application:

- Large steel beams and profiles

Profiler

| Band width b x band thickness S | TPI | |||

|---|---|---|---|---|

| mm | Inch | 2/3 | 3/4 | 4/6 |

| 41 x 1.30 | 1 5/8 x 0.050 | C | C | C |

| 54 x 1.30 | 2 1/8 x 0,50 | C | C | C |

| 54 x 1.60 | 2 1/8 x 0,063 | C | C | C |

| 67 x 1.60 | 2 5/8 x 0,063 | C | C |

Aggressive M42 bi-metal band saw blades

Aggressive M42 bi-metal blades with a combo-tooth form "CP" and an increased rake angle are used under stable operating conditions for difficult to machine materials.

Application:

- Iron materials up to approx. 1400 N/mm²2 Tensile strength

- Rust and acid-resistant steels

- Titanium and nickel alloys

Aggressive

| Band width b x band thickness S | TPI | ||||||

|---|---|---|---|---|---|---|---|

| mm | Inch | 0,75/1,25 | 1,1/1,4 | 1,4/2 | 2/3 | 3/4 | 4/6 |

| 27 x 0.90 | 1 1/16 x 0.035 | CP | CP | CP | |||

| 34 x 1.10 | 1 3/8 x 0.042 | CP | CP | CP | |||

| 41 x 1.30 | 1 5/8 x 0.050 | CP | CP | CP | |||

| 54 x 1.30 | 2 1/8 x 0,50 | CP | CP | ||||

| 54 x 1.60 | 2 1/8 x 0,063 | CP | CP | CP | |||

| 67 x 1.60 | 2 5/8 x 0,063 | CP | CP | CP |

M51 bi-metal band saw blades

Aggressive M51 have tooth tips made of HSS M51 and are used for difficult to machine materials with a strength up to approx. 1700 N/mm2 as well as for an increase the service life of the band saw blade.

Application:

- Iron materials up to approx. 1700 N/mm²2 Tensile strength

- Rust and acid-resistant steels

- Titanium and nickel alloys

M51 bi-metal band saw blades

Aggressive M51

| Band width b x band thickness S | TPI | |||||

|---|---|---|---|---|---|---|

| mm | Inch | 0,75/1,25 | 1,4/2 | 2/3 | 3/4 | 4/6 |

| 27 x 0.90 | 1 1/16 x 0.035 | CP | CP | CP | ||

| 34 x 1.10 | 1 3/8 x 0.042 | CP | CP | CP | ||

| 41 x 1.30 | 1 5/8 x 0.050 | CP | CP | CP | CP | |

| 54 x 1.30 | 2 1/8 x 0,50 | CP | CP | CP | ||

| 54 x 1.60 | 2 1/8 x 0,063 | CP | CP | CP | CP | |

| 67 x 1.60 | 2 5/8 x 0,063 | CP | CP | CP | ||

| 80 x 1.60 | 3 1/8 x 0.63 | CP | CP |

Kohlenstoff-Sägebänder

CS

CS mit Standard-Verzahnung “N” und Klauen- Verzahnung “KP”mit flexiblem Bandrücken.

Anwendung:

• einfach zu zerspannende Werkstoffe

• für unlegierte Stähle niedriger Festigkeit

| Bandbreite b x Bandstärke S | ZpZ | ||||||||

| blade width b x blade thicknessS | tpi | ||||||||

| mm | Zoll/inch | 3 | 4 | 6 | 8 | 10 | 14 | 18 | 22 |

| 6 x 0,65 | 1/4 x 0,025 | KP | N/KP | N | N | N | |||

| 8 x 0,65 | 5/16 x 0,025 | KP | N/KP | N | N | N | N | N | |

| 10 x 0,65 | 3/ 8x 0,025 | N/KP | N/KP | N | N | N | N | N | |

| 13 x 0,65 | 1/2 x 0,025 | N/KP | N/KP | N | N | N | N | N | |

| 16 x 0,65 | 5/8 x 0,025 | N | N/KP | N | N | N | |||

| 16 x 0,80 | 5/8 x 0,032 | N/KP | N/KP | N | N | N | |||

| 20 x 0,80 | 3/4 x 0,032 | KP | N/KP | N/KP | N | N | N | ||

| 25 x 0,90 | 1 x 0,035 | KP | N/KP | N/KP | N | N | N | ||

CS-Plus

CS-Plus mit Standard-Verzahnung “N” und Klauen-Verzahnung “KP” mit federhart vergütetem Bandrücken und gehärteten Zahnspitzen.

Anwendung:

• für niedriglegierte Stähle

• für Stähle mittlerer Festigkeit

| Bandbreite b x Bandstärke S | ZpZ | ||||||||

| blade width b x blade thickness S | tpi | ||||||||

| mm | Zoll/inch | 3 | 4 | 6 | 8 | 10 | 14 | 18 | 22 |

| 6 x 0,65 | 1/4 x 0,025 | KP | KP | N | N | N | N | N | |

| 8 x 0,65 | 5/16 x 0,025 | KP | KP | N | N | N | N | N | |

| 10 x 0,65 | 3/8 x 0,025 | N/KP | N/KP | N | N | N | N | N | |

| 13 x 0,65 | 1/2 x 0,025 | N/KP | N/KP | N | N | N | N | ||

| 16 x 0,65 | 1/2 x 0,025 | N/KP | N | N | N | N | |||

| 16 x 0,80 | 5/8 x 0,032 | N/KP | N/KP | N | N | N | |||

| 20 x 0,80 | 3/4 x 0,032 | KP | N/KP | N/KP | N | N | N | ||

| 25 x 0,90 | 1 x 0,035 | KP | N/KP | N/KP | N | N | N | ||